A

Your helper

Saturday, January 10, 2015

Types of thermodynamical process like Adiabatic Process, Isochoric Process,Isobaric Process,Isothermal Process,Isothermal expansion of an ideal gas,Adiabatic Expansion of an ideal gas,Adiabatic process,otto cycle ,first law's of thermodynamics ,power stroke of otto cycle is adiabatic Expansion and its relation to mitochondria cell organelle as power house of cell,Petrol and Diesel Engines in Mercedes-Benz,Top 10 petrol cars to buy instead of a diesel

Kinds of Thermodynamic Processes

In this section we describe four specific kinds of thermodynamic processes that

occur often in practical situations. These can be summarized briefly as “no heat

transfer” or adiabatic, “constant volume” or isochoric, “constant pressure” or

isobaric, and “constant temperature” or isothermal. For some of these processes

we can use a simplified form of the first law of thermodynamics.

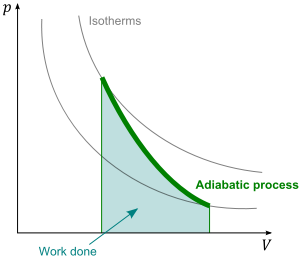

Adiabatic Process

An adiabatic process (pronounced “ay-dee-ah-bat-ic”) is defined as one with no

heat transfer into or out of a system;Q = 0.We can prevent heat flow either by

surrounding the system with thermally insulating material or by carrying out the

process so quickly that there is not enough time for appreciable heat flow. From

the first law we find that for every adiabatic process,

U2 - U1 = delU = -W (adiabatic process)

When a system expands adiabatically, W is positive (the system does work on its

surroundings), so change inU(internal energy)is negative and the internal energy decreases. When a system is compressed adiabatically,W is negative (work is done on the system by its

surroundings) and U increases. In many (but not all) systems an increase of internal

energy is accompanied by a rise in temperature, and a decrease in internal

energy by a drop in temperature as shown in the following figure

The compression stroke in an internal-combustion engine is an approximately

adiabatic process. The temperature rises as the air–fuel mixture in the cylinder is

compressed. The expansion of the burned fuel during the power stroke is also an

approximately adiabatic expansion with a drop in temperature. In Section 19.8

we’ll consider adiabatic processes in an ideal gas.

Isochoric Process

An isochoric process (pronounced “eye-so-kor-ic”) is a constant-volume process.

When the volume of a thermodynamic system is constant, it does no work on its

surroundings. Then W=0 and

In an isochoric process, all the energy added as heat remains in the system as an

increase in internal energy. Heating a gas in a closed constant-volume container is

an example of an isochoric process. The processes ab and cd in Example below are

also examples of isochoric processes. (Note that there are types of work that do not

involve a volume change. For example, we can do work on a fluid by stirring it. In

some literature, “isochoric” is used to mean that no work of any kind is done.)

Example: Comparing thermodynamic processes

The pV-diagram of Fig. below shows a series of thermodynamic processes. In process ab, 150 J of heat is added to the system; in process bd, 600 J of heat is added. Find (a) the internal energy change in process ab; (b) the internal energy change in process abd (shown in light blue); and (c) the total heat added in process acd (shown in dark blue).

An isochoric process (pronounced “eye-so-kor-ic”) is a constant-volume process.

When the volume of a thermodynamic system is constant, it does no work on its

surroundings. Then W=0 and

In an isochoric process, all the energy added as heat remains in the system as an

increase in internal energy. Heating a gas in a closed constant-volume container is

an example of an isochoric process. The processes ab and cd in Example below are

also examples of isochoric processes. (Note that there are types of work that do not

involve a volume change. For example, we can do work on a fluid by stirring it. In

some literature, “isochoric” is used to mean that no work of any kind is done.)

Example: Comparing thermodynamic processes

The pV-diagram of Fig. below shows a series of thermodynamic processes. In process ab, 150 J of heat is added to the system; in process bd, 600 J of heat is added. Find (a) the internal energy change in process ab; (b) the internal energy change in process abd (shown in light blue); and (c) the total heat added in process acd (shown in dark blue).

A pV-diagram showing the various thermodynamic processes.

SOLUTION

EXECUTE: (a) No volume change occurs during process ab, so the

system does no work:Wab = 0,and so delUab= Qab = 150 J.

system does no work:Wab = 0,and so delUab= Qab = 150 J.

(b) Process bd is an expansion at constant pressure, so from Eq.given below

Wabd = Wab + Wbd = 0 + 240 J = 240 J and the total heat is

Qabd = Qab + Qbd = 150 J + 600 J = 750 J

Change(Uabd) = Qabd - Wabd = 750 J - 240 J = 510 J

(c) Because is independent of the path from a to d, the internal energy change is the same for path acd as for path abd:

Isothermal Process

An isothermal process is a constant-temperature process. For a process to be isothermal, any heat flow into or out of the system must occur slowly enough that thermal equilibrium ismaintained. In general, none of the quantities delU,Q or W is zero in an isothermal process.

In some special cases the internal energy of a system depends only on its temperature,not on its pressure or volume. The most familiar system having this special property is an ideal gas, as we’ll discuss in the next section. For such systems, if the temperature is constant, the internal energy is also constant; delU = 0 and Q=W.That is, any energy entering the system as heat Q must leave it again as work W done by the system Example 19.1, involving an ideal gas, is an example of an isothermal process in which U is also constant. For most systems other than ideal gases, the internal energy depends on pressure as well as temperature, so U may vary even when T is constant.

Example 19.1 An Isothermal expansion of an ideal gas is as following

Figure below shows a pV-diagram for these four processes for a constant amount of an ideal gas. The path followed in an adiabatic process (a to 1) is called an adiabat. A vertical line (constant volume) is an isochor, a horizontal line (constant pressure) is an isobar, and a curve of constant temperature (shown as light blue lines in Fig. below) is an isotherm.

Understanding of These thermodynamical path through a PV Graph is mandatory to solve a lot of Complicated problems in Thermodynamics.

Four different processes for a constant amount of an ideal gas, all starting at state a.For the adiabatic process,Q=0;for the isochoric process,W = 0;and for the isothermal process,Change in U(internal Energy of System) = 0.The temperature increases only

during the isobaric expansion.

during the isobaric expansion.

http://t.co/jju15nzgtj

Working of Mercedes Benz Petrol and Diesel Engines and Adiabatic process as Power Stroke.. pic.twitter.com/LMFztmjD2n

— Abraham Malik (@brhmmlk93_malik) March 25, 2015can't Imagine or think Outside the Progm Embeded as a code inside in this Struct,The Future of http://t.co/eQSpd40fb2 pic.twitter.com/oSpuSrOVDJ

— Abraham Malik (@brhmmlk93_malik) March 23, 2015http://t.co/eQSpd40fb2

Human Genetic information is Compressed by God in a Double Helical Structure.Excellent Data Co pic.twitter.com/lcCWBqE5dc

— Abraham Malik (@brhmmlk93_malik) March 23, 2015So applying the first law of thermodynamics

- For the ideal gas work done is given by

Hence a positive work done in adiabatic expansion reduces the internal energy of system thus lowering the temperature because internal energy is the function of temperature.Hence when we open a champagne, the pressurized gases inside the bottle expand rapidly and do

work on the outside air W > 0 . There is no time for the gases to exchange heat with their surroundings, so the expansion is adiabatic Q= 0.Hence the internal energy of the expanding gases decreases (ΔU=- W < 0 and their temperature drops. This makes water vapor condense

and form a miniature cloud as shown below.This same phenomenon is also responsible for power providing stroke in petrol engines amazing.The beauty of such adiabatic process is that is happens very very fast like compression and rarefaction of sound which is also adiabatic.

Adiabatic processes in ideal gases: For an adiabatic process for an ideal gas, the quantities TV^Y-1 and PV^Y are constant. The work done by an ideal gas during an adiabatic expansion can be expressed in terms of the initial and final values of temperature, or in terms of the initial and final values of pressure and volume.

Adiabatic processes in ideal gases: For an adiabatic process for an ideal gas, the quantities TV^Y-1 and PV^Y are constant. The work done by an ideal gas during an adiabatic expansion can be expressed in terms of the initial and final values of temperature, or in terms of the initial and final values of pressure and volume.

Adiabatic Ideal Gas: Relating V, T, and p

We can derive a relationship between volume and temperature changes for an infinitesimal adiabatic process in an ideal gas:

The above equation Is defined for isochoric process where change in volume is zero,ie where volume is constant throughout the process which can be shown by the following figure:

In Otto cycle (Petrol engine this Adiabatic process is the power stroke) ie this adiabatic process where heat gain or absorbed by the system is zero is the process in the heat engine providing maximum power because it take place very fast such that system is not having enough time to exchange heat with the surrounding.

We describe Otto cycle here.This is the thermodynamical process which undergoes four different processes in a sequential steps hence also called four stroke engine used in lightweight vehicles:

First of all, what the heck is the Atkinson Cycle and why should we care? Naturally, it's a bit complicated, but basically in a modern Atkinson Cycle engine, the intake valve is held open longer than normal to allow a reverse flow of intake air into the intake manifold and allowing for a smaller compression ratio than the expansion ratio, making the engine more efficient with a slight reduction in overall power. Consult the all-knowing Wiki for more on that.

Most hybrid vehicles' gas-powered engines use an Atkinson Cycle, including the Toyota Prius and GM's 2-Mode Hybrid trucks and SUVs. According to the reliable Lyle Dennis of GM-Volt.com, the Chevy Volt will not use an Atkinson Cycle engine, instead relying on the standard Otto Cycle. For what it's worth, we also know that the Volt's 1.4-liter four cylinder engine will be controlled and monitored by all manner of electronic gadgetry, and we're sure the automaker has done its homework on making it as efficient as possible.

How Diesel Engine is Different From Petrol Engine And What is the difference between otto Cycle and Steam.?

Today Know About Mercedes Diesel And Petrol Engine:

Powerful, efficient and clean: the latest Mercedes-Benz diesel technology in the CLA. The engine impresses by delivering high pulling power

The

4-cylinder in-line diesel engine with common rail direct injection

gives our customers the freedom to explore places around them without

worrying about the running costs.

The highlights of the 4-cylinder diesel engine.

The

4-cylinder diesel engine demonstrate hallmark Mercedes qualities: they

are modest when it comes to fuel consumption, are low on emissions and

impress with their significantly improved quiet-running characteristics

and their reduced vibrations.

In order to keep the engine weight as low as possible, the engine is fitted with a crankshaft with four counterweights and a crankcase bearing with individual bearing caps.

The new CLA 200 CDI has a power output of 100 kW and maximum torque of 300 Nm. As the fourth generation of common-rail diesel technology the engine boast an injection pressure increased to 1800 bar, optimised combustion chambers plus precise solenoid injectors. The high ignition pressure and a turbocharger with a variable nozzle turbine ensure an effortlessly superior torque curve and corresponding pulling power in every engine speed range.

In order to keep the engine weight as low as possible, the engine is fitted with a crankshaft with four counterweights and a crankcase bearing with individual bearing caps.

The new CLA 200 CDI has a power output of 100 kW and maximum torque of 300 Nm. As the fourth generation of common-rail diesel technology the engine boast an injection pressure increased to 1800 bar, optimised combustion chambers plus precise solenoid injectors. The high ignition pressure and a turbocharger with a variable nozzle turbine ensure an effortlessly superior torque curve and corresponding pulling power in every engine speed range.

Further

efficiency measures: The diesel drive systems are equipped with the ECO

start/stop function which switches off the engine temporarily when the

vehicle is stationary. Even greater driving efficiency can be achieved

with the help of the standard-fit ECO display which indicates how

economically the vehicle is being driven at any given moment. This

information can be used to help the driver adopt a driving style which

provides for optimum fuel consumption in the current driving situation.

Note : Not conducive for driving in water-logged roads with still water depth more than 25 cm.

Note : Not conducive for driving in water-logged roads with still water depth more than 25 cm.

The CLA 200 CDI attains its maximum torque of 300 Nm from just 1600 rpm.

Setting

the standard: the petrol engine in the CLA combines, dynamic power

delivery and effortlessly superior ride comfort with low fuel

consumption

and exemplary emission characteristics.

and exemplary emission characteristics.

The

CLA-Class petrol engine is the best choice for people who want to

experience explicit driving performance with phenomenal top speed and

acceleration. The 4-cylinder petrol engine in the CLA 200 features

homogeneous direct injection, piezo injectors and turbocharging with a

displacement of 1991 cc.

The

4-cylinder petrol engine of CLA 200 comes with 135 kW and a maximum

torque of 300 Nm. This engine is extremely low on emissions. The

combination of the third-generation Mercedes-Benz high-pressure direct

injection system with precise piezo injectors and the enhanced

spray-guided combustion process facilitates virtually total combustion

and thus allows the fuel to be used particularly efficiently. The

variable valve control results in an optimum cylinder charge level which

has a beneficial effect on fuel consumption, as do the lower weight,

reduced internal friction and ancillaries controlled on an on-demand

basis. Turbocharging makes for enhanced responsiveness and higher torque

in every engine speed range.

Further efficiency measures. The standard ECO start/stop function also enhances the economic efficiency of the engine. Furthermore, the standard-fit ECO display provides feedback about how efficiently the car is being driven. On the basis of this information, the driver can adjust his or her driving style in order to attain the optimum fuel consumption in the current driving situation.

when it comes to both torque and power, plus exemplary quiet-running characteristics, not to mention appropriately low fuel consumption and emissions.

The high-pressure direct injection via precise piezo injectors and an enhanced

combustion process facilitate virtually total combustion and thus higher efficiency, which means that the fuel can be used more efficiently. The variable valve control results in an optimum cylinder charge level and therefore consumption benefits, which also comes courtesy of the lower weight, less internal friction plus ancillaries

controlled as required. And last but not the least, the standard-specification ECO start/stop function raises the efficiency of the engine.

The new petrol engine is developed with the aim of reducing fuel consumption and emissions without compromising on output and ride comfort. The A 180 BlueEFFICIENCY comes with 1595 cc and 90 kW plus a maximum torque of 200 Nm. The petrol engines are low on emission and thus comply with the requirements of emission class Bharat Stage IV.

The oil and water pumps are activated as required. The belt forces and component weights have been further reduced.

The diesel engine has the ECO start/stop function and ECO display fitted as standard feature. All these characteristics have a positive effect on fuel consumption and emissions.

Further efficiency measures. The standard ECO start/stop function also enhances the economic efficiency of the engine. Furthermore, the standard-fit ECO display provides feedback about how efficiently the car is being driven. On the basis of this information, the driver can adjust his or her driving style in order to attain the optimum fuel consumption in the current driving situation.

Effortlessly superior in performance, responsible in consumption

The

GL-Class engines offer a potent combination of enhanced performance and

reduced consumption. Output has risen by up to 22 percent, for example,

while consumption in comparison with comparable-performance vehicles in

the previous model series has reduced by up to 20 percent.

The <a class="tooltip" onclick="return false;" href="/content/india/mpc/mpc_india_website/enng/home_mpc/passengercars/tooltips/e/ecostartstop.html" id="/content/india/mpc/mpc_india_website/enng/home_mpc/passengercars/tooltips/e/ecostartstop">ECO start/stop function</a> makes an important contribution to reducing consumption.<br />

The <a class="tooltip" onclick="return false;" href="/content/india/mpc/mpc_india_website/enng/home_mpc/passengercars/tooltips/e/ecostartstop.html" id="/content/india/mpc/mpc_india_website/enng/home_mpc/passengercars/tooltips/e/ecostartstop">ECO start/stop function</a> makes an important contribution to reducing consumption.<br />

6-cylinder diesel engine

An

optimised, uprated V6 diesel engine is available for the GL to further

reduce fuel consumption and emissions. It is equipped with, amongst

other features, third-generation common rail direct injection and also

has BlueTEC, an exhaust gas turbocharger and intercooling.

The diesel engine also has a maintenance-free soot particulate filter and meets the requirements of the Euro 6 emissions standard.

The diesel engine also has a maintenance-free soot particulate filter and meets the requirements of the Euro 6 emissions standard.

- Huge output: the exhaust gas turbocharger with variable turbine geometry (VTG charger) makes high output as well as high torque possible from a low engine speed. The electrical adjustment feature for the VTG charger gives precise and swift boost pressure control

- Effective and efficient: the third-generation common rail direct injection with system pressure of up to 1600 bar and piezo injectors as well as dual pilot injection ensure precisely controlled combustion. Up to 5 injections per cycle are possible. This reduces consumption, noise and emissions, while at the same time improving response and handling

- Clean technology: BlueTEC is a particularly low-emission diesel technology; for this reason the BlueTEC model is one of few vehicles to date to comply with the strict Euro 6 emissions standard

- Economy as standard: The ECO start/stop function is available as standard The ECO display in the instrument cluster supplies efficiency data on the driver's driving style, offering a motivation to reduce fuel consumption.

4-cylinder in-line engine

The newly developed 4-cylinder power plant, with a displacement of 1.6 litres, direct petrol injection, variable valve timing and a turbocharger, offers excellent figureswhen it comes to both torque and power, plus exemplary quiet-running characteristics, not to mention appropriately low fuel consumption and emissions.

The high-pressure direct injection via precise piezo injectors and an enhanced

combustion process facilitate virtually total combustion and thus higher efficiency, which means that the fuel can be used more efficiently. The variable valve control results in an optimum cylinder charge level and therefore consumption benefits, which also comes courtesy of the lower weight, less internal friction plus ancillaries

controlled as required. And last but not the least, the standard-specification ECO start/stop function raises the efficiency of the engine.

The new petrol engine is developed with the aim of reducing fuel consumption and emissions without compromising on output and ride comfort. The A 180 BlueEFFICIENCY comes with 1595 cc and 90 kW plus a maximum torque of 200 Nm. The petrol engines are low on emission and thus comply with the requirements of emission class Bharat Stage IV.

The

4-cylinder in-line diesel engine with common rail direct injection.

This engine is installed transversely and is designed for

front-wheel-drive vehicles.

Design

The

cylinder head has a special intake port as well as an intake valve lift

adapted to the downsized displacement. The engine is installed

transversely in the vehicle.

The new engine concept additionally accords due consideration to variants such as right-hand drive models

In order to keep the engine weight as low as possible, the engine is fitted with a crankshaft with four counterweights and a crankcase bearing with individual bearing caps.

In developing the new motor mounts, due consideration was also given to comfortable NVH characteristics for the engine.

The new engine concept additionally accords due consideration to variants such as right-hand drive models

In order to keep the engine weight as low as possible, the engine is fitted with a crankshaft with four counterweights and a crankcase bearing with individual bearing caps.

In developing the new motor mounts, due consideration was also given to comfortable NVH characteristics for the engine.

Mixture formation:

Common-rail

direct injection makes a system pressure of 2000 bar possible. The

solenoid valve technology creates the conditions for highly flexible

injection timing and smooth engine operation, as well as a high output

combined with low fuel consumption and low emissions.

The geometry of the flat combustion chamber design and a low compression ratio minimise untreated emissions, especially of NOx. The maximum ignition pressure of up to 180 bar makes for a high output and low pollutant

emissions.

The single-stage turbocharger ensures a high power output and high torque already at low engine speeds. The VTGturbocharger’s electrical adjustment ensures fast, precise charge-pressure control.

The charge-air ducting has been designed to minimise pressure loss and noise.

The geometry of the flat combustion chamber design and a low compression ratio minimise untreated emissions, especially of NOx. The maximum ignition pressure of up to 180 bar makes for a high output and low pollutant

emissions.

The single-stage turbocharger ensures a high power output and high torque already at low engine speeds. The VTGturbocharger’s electrical adjustment ensures fast, precise charge-pressure control.

The charge-air ducting has been designed to minimise pressure loss and noise.

Environment:

The exhaust gas recirculation system is modular in design. It is highly efficient on account of low pressure loss, an on-demand cooler bypass and an effective exhaust gas recirculation valve.The oil and water pumps are activated as required. The belt forces and component weights have been further reduced.

The diesel engine has the ECO start/stop function and ECO display fitted as standard feature. All these characteristics have a positive effect on fuel consumption and emissions.

An Otto cycle is an idealized thermodynamic cycle that describes the functioning of a typical spark ignition piston engine.[It is the thermodynamic cycle most commonly found in automobile engines.

4-cylinder

in-line engine. The 4-cylinder powerplant with a displacement of 1.6

litres, direct petrol injection, variable valve timing and a

turbocharger offers excellent torque and power and exemplary

quiet-running characteristics, not to mention appropriately low fuel

consumption and emissions.

The petrol engine was

developed with the aim of substantially reducing fuel consumption and

emissions without compromising on output and ride comfort. The result:

progressive, trendsetting engine technology.

The high-pressure direct

injection via precise piezo injectors and an enhanced combustion process

facilitate virtually total combustion and thus higher efficiency, which

means that the fuel can be used more efficiently. Direct injection

allows an increase in the compression ratio compared to the previous

duct injection, which makes for higher efficiency. The variable valve

control results in an optimum cylinder charge level and therefore

consumption benefits, which also come courtesy of the lower weight, less

internal friction plus ancillaries controlled as required. And last but

not least the petrol engine has the ECO start/ stop function and ECO

display fitted as standard. Both help the driver to reduce consumption

even further. Over and above this the BlueEFFICIENCY measures such as

thermal management for an engine warm-up phase that is kept as short as

possible, an oil pump controlled as required plus a particularly

efficient alternator.

But diesel's reputation has plummeted after new research, revealed in The Sunday Times, found that the fuel is responsible for most of the pollution that causes 29,000 deaths per year in Britain. At the same time, technology breakthroughs mean that petrol-powered cars now rival diesels for cost-effectiveness.

The report, commissioned by Defra, the environment ministry, blamed diesel vehicles for a rise in nitrogen dioxide emissions and high levels of tiny toxic particulates that can pass through the lungs to enter every organ in the body. Although much of the pollution is down to buses, lorries and taxis, David Carslaw, of King's College London, a co-author of the report, said that air quality could still be improved if motorists switched from diesel to petrol-powered cars.

“From an air quality point of view it is hard to find a major disadvantage with modern petrol cars, "What most people would say is that petrol is worse than diesel for CO2 emissions. This is still true but even here, a small, modern petrol vehicle can be very low emitting, and will give diesel a run for its money.”The higher purchase cost of some diesel cars threatens to make them redundant against a new generation of small, efficient, turbocharged petrol models. For example, the petrol-powered Ford Fiesta 1.0 Zetec EcoBoost costs £13,895 and returns 65.7mpg. A 1.6 TDCi diesel version of the Fiesta appears much more economical at 85.6mpg but it costs £1,400 more. You would have to travel 81,000 miles to make up the difference in the money you save on fuel.

That's an extreme example but even so, you will generally need to be travelling more than 15,000 miles a year to justify the extra cost of a diesel car. Depreciation is roughly the same, whichever type of engine you choose, according to Cap, a vehicle pricing company.

So if now is the time to switch to petrol cars, here are 10 that will give you just as much for your money as a diesel ‒ and the knowledge that you're doing your bit for air quality, even as the HGVs chug past.

City car Fiat Panda Lounge 0.9 TwinAir 5dr, £11,295 Green credentials: 67.3mpg, 99g/km, tax band A

Of the new generation of small-capacity, turbocharged petrol engines, the Twin Air has received most criticism for failing to get close to its official fuel consumption figure. All the same, it is economical and brimful of character.

Top 10 petrol cars to buy instead of a diesel

Diesel's reputation has plummeted after new research, revealed in The Sunday Times, found that the fuel is responsible for most of the pollution that causes 29,000 deaths per year in Britain.

FOR YEARS it's been accepted that the greenest cars are diesel-powered. More fuel efficient and emitting less CO2, they are also fitted with special filters that trap harmful emissions.But diesel's reputation has plummeted after new research, revealed in The Sunday Times, found that the fuel is responsible for most of the pollution that causes 29,000 deaths per year in Britain. At the same time, technology breakthroughs mean that petrol-powered cars now rival diesels for cost-effectiveness.

The report, commissioned by Defra, the environment ministry, blamed diesel vehicles for a rise in nitrogen dioxide emissions and high levels of tiny toxic particulates that can pass through the lungs to enter every organ in the body. Although much of the pollution is down to buses, lorries and taxis, David Carslaw, of King's College London, a co-author of the report, said that air quality could still be improved if motorists switched from diesel to petrol-powered cars.

“From an air quality point of view it is hard to find a major disadvantage with modern petrol cars, "What most people would say is that petrol is worse than diesel for CO2 emissions. This is still true but even here, a small, modern petrol vehicle can be very low emitting, and will give diesel a run for its money.”The higher purchase cost of some diesel cars threatens to make them redundant against a new generation of small, efficient, turbocharged petrol models. For example, the petrol-powered Ford Fiesta 1.0 Zetec EcoBoost costs £13,895 and returns 65.7mpg. A 1.6 TDCi diesel version of the Fiesta appears much more economical at 85.6mpg but it costs £1,400 more. You would have to travel 81,000 miles to make up the difference in the money you save on fuel.

That's an extreme example but even so, you will generally need to be travelling more than 15,000 miles a year to justify the extra cost of a diesel car. Depreciation is roughly the same, whichever type of engine you choose, according to Cap, a vehicle pricing company.

So if now is the time to switch to petrol cars, here are 10 that will give you just as much for your money as a diesel ‒ and the knowledge that you're doing your bit for air quality, even as the HGVs chug past.

City car Fiat Panda Lounge 0.9 TwinAir 5dr, £11,295 Green credentials: 67.3mpg, 99g/km, tax band A

Of the new generation of small-capacity, turbocharged petrol engines, the Twin Air has received most criticism for failing to get close to its official fuel consumption figure. All the same, it is economical and brimful of character.

Subscribe to:

Posts (Atom)